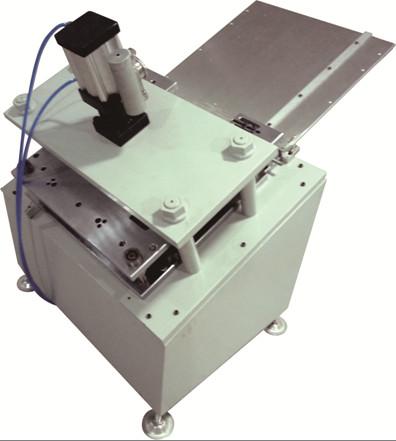

RFID Card Inlay Sheet Chip Hole Die Cutter YHP-3000 One Time

Punching

1.Machine Introduction of RFID Card Inlay Sheet Chip Hole Die Cutter YHP-3000 One Time

Punching

RFID Card INLAY Sheet Hole Puncher YHP-A+ is designed to punch both

two side position holes and chip fixing holes (like 24 hole for 3*8

layout) for installing COB chips in the INLAY sheet middle layer in

the process of RFID card INLAY sheet production.

The machine is specially designed for punching the side positioning

holes (Usually two holes) and contactless or RFID card chip fixing

holes on INLAY middle sheet at the same time.

This hole punching machine uses to punch of the positioning hole

and the clearance hole on PVC, PETG and ABS sheets with different

thickness and size for contactless cards (RF cards). Control by the

servo system and use the precision mold to punch, which ensure the

quality of the products and improve productivity, only need one

operator.

In the machine structure, the machine is easy to operate and

maintain, which enhances the service life of machine and

productivity.

2. Feature Descriotion of RFID Card Inlay Sheet Chip Hole Die Cutter YHP-3000 One Time

Punching

- The position precision of all the punched holes is made accurate

because all the holes are punched at the same time.

- It features very high speed, very easy operation and very high

precision.

- The mechanical structure is so reasonably designed that the punch

mould can be easily changed as per the different INLAY sheet layout

(such as 3×8, 4×8 and 5×5 layout).

Main technical parameters

Technical Parameters

1. Speed: 800-1200 sheets per hour.

2. Operator needed: 1 person

3. Compressed air: 5-6kg/cm2 30 liters/minute

4. Gross weight: 18 kg

5. Dimension: L600×W550×H800

| Dimensions | L600×W550×H800 |

| G.W | 50kg |

| Power | AC220V 50/60HZ 1.5KW |

| Air pressure | 5-6kg/cm² |

| Air consumption | 50L/min |

| Control mode | servo positioning + PLC control |

| Accuracy | Servo division per step = 0.0125mm |

| Mechanical adjustment | 0.01mm |

| Operator | 1 person |

| Output | 800-1000 sheets per hour |

| Applicable layout | 3×8, 4×8, 5×5 etc |

| Applicable material (carrier) | Plastic materials like PVC, ABS and PETG |

| Compressed air: | 5-6kg/cm2, 50L/min |

| cutting speed (max.) | 800-1000 sheets per hour |

| Power supply | AC220V, 50/60HZ |

| Position precision | 0.05mm |

| Power | 1kW |

| Weight | around 50 kg |

| Dimension | L600×W550×H800 |

3. More Characters of RFID Card Inlay Sheet Chip Hole Die Cutter YHP-3000 One Time

Punching

1. Punch the hole for the chip of the inlay, which ensures the

modules and the PVC embedding on the same plane and protects the

chips.

2. The machine has two molds with two different sides, it can be

used for different production technology, just press the switch to

select the mold.

3. The pitch and the size of the punching mold can be adjusted

according to the requirement.

4. The cylinder drives punching mold up and down with the low

noise.

5. PLC control and can be punched different layout,

6. Use the precision mold to punch and ensure the quality of the

products.

7. The life span of the mold is: It only needs to be whetted every

two million times punching

8. Punching with the low noise.

9. Materials are loaded using the dowel pin, easy to adjust.

10. Use the servo system to position which ensure the position

accurately

11. Use the PLC and the touch screen, stable and visualized.

12 .HMI system make communication easier.