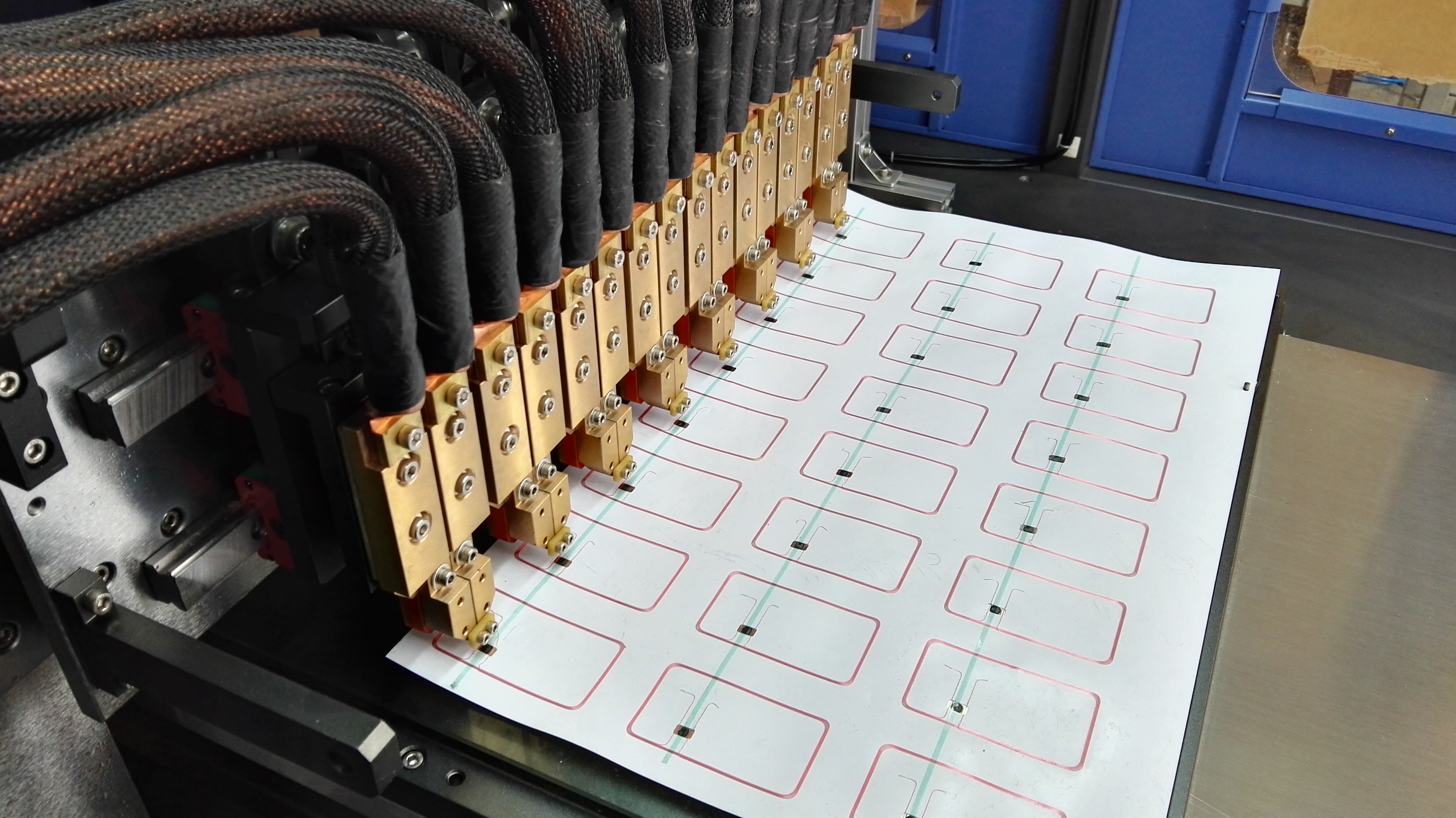

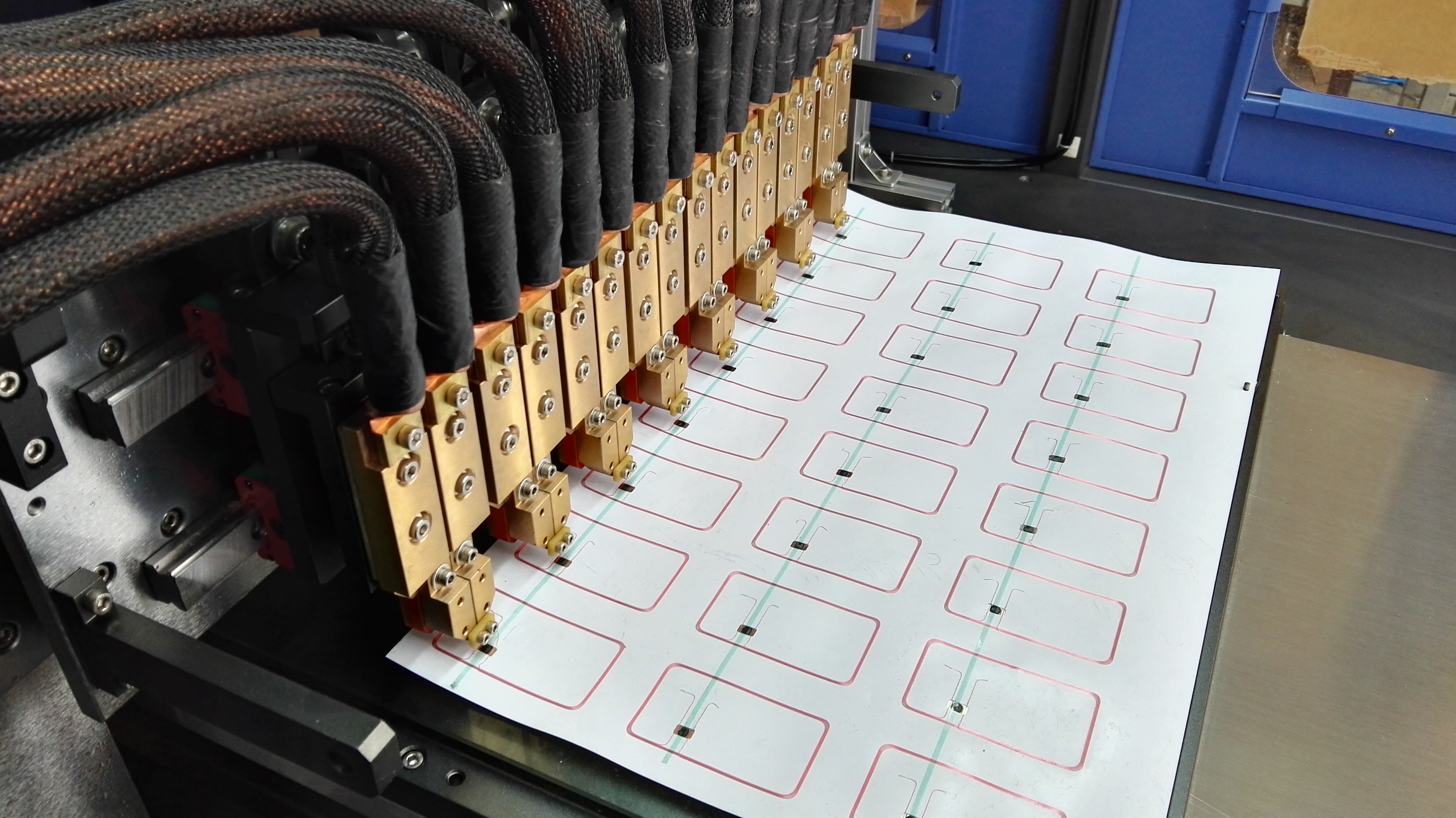

RFID Card INLAY Sheet 5 Welding heads Chip Antenna Bonder YCB-15

1. Introduction of RFID Card INLAY Sheet 5 Welding heads Chip

Antenna Bonder YCB-15

The machine is designed for bonding or welding the contactless card

antennas and chips together in an automatic and speedy way.

It is also called Contactless Card Chip Bonding Machine/RFID Card

INLAY Sheet Chip Antenna Bonder/Automatic RFID Card Chip Welding

Machine YCB-15

As an indispensable machine of RFID card Inlay or Prelam sheet

production line, Contactless Card Chip Bonding Machine YCB-15 is

also known as named as RFID Card INLAY Sheet Chip Antenna Bonding

or Welding Machine, Automatic Chip Wire Bonding Machine or

Automatic RFID Card Chip Welder YCB-15.

2. Description of RFID Card INLAY Sheet 5 Welding heads Chip Antenna Bonder YCB-15

- In order to ensure its reliability, the key components such as PLC,

touch screen and servo system from Mitsubishi are applied inside.

- The lead screw by German REXROTH is applied to ensure precise

motion precision.

- The bonding unit is dual-pulse high-frequency inverting welding

system to ensure fast and quality welding, and the instant current

output or instant voltage output can be freely selected.

- The bonding is fast in speed and good in quality.

| Production Speed | 2500-3500 units per hour |

| Bonding head number | 5 for the layout of 5*5. |

| Motion precision | 0.0125mm |

| Mechanical adjustment | 0.01mm |

| Compressed air | 6 kg/cm2 |

| Air Consumption | 50 L/min. |

| Power | 15KW |

| Power supply | AC220V 50/60HZ 100A |

| Weight | 1000 KG |

| Dimension | L1300×W900×H1700mm |

| Model NO | YCB-15 |

| Overall Dimension | L1400 *W1200 *H1800mm |

| Machine weight | About1000kgs |

| Electricity input | AC 220V/50-60 Hz current : 25A |

| Power consumption | 4kw |

| Compressed air | 6.00kg/CM² |

| Air consumption | 250L/min |

| Control technology | servo positioning+ PLC Control |

| Servo precision | X,Y= 0.0125MM |

| Tolerance | ±0.1mm |

| Operator | 1 person |

| Pass rate | 99.5% |

| Applicable materials | the inlay finished module placing and wire embedding |

| output speed | 2500-3500CPH |

3. Parameter of RFID Card INLAY Sheet 5 Welding heads Chip Antenna

Bonder YCB-15

- ) Speed: around 2500-3500 units per hour

- ) Bonding head number: 5 for the layout of 5*5.

- ) Motion precision: 0.0125mm

- ) Mechanical adjustment: 0.01mm

- ) Compressed air: 6 kg/cm2

- ) Air Consumption: 50 L/min.

- ) Power:15KW

- ) Power supply: AC220V 50/60HZ 100A

- ) Weight: 1000 KG

- ) Dimension: L1300×W900×H1700mm

4. More details of RFID Card INLAY Sheet 5 Welding heads Chip

Antenna Bonder YCB-15

The chip welding machine is steady and can be adjusted, it only

need one operator.

In the machine structure, the machine is easy to operate and

maintain, which enhances the service life of machine and the

productivity.

The appearance and style of the machine is concise and easy,

rationalization and hommization, and the machine interface protect

the safety of operators. It can be also customized by client's

requirement.