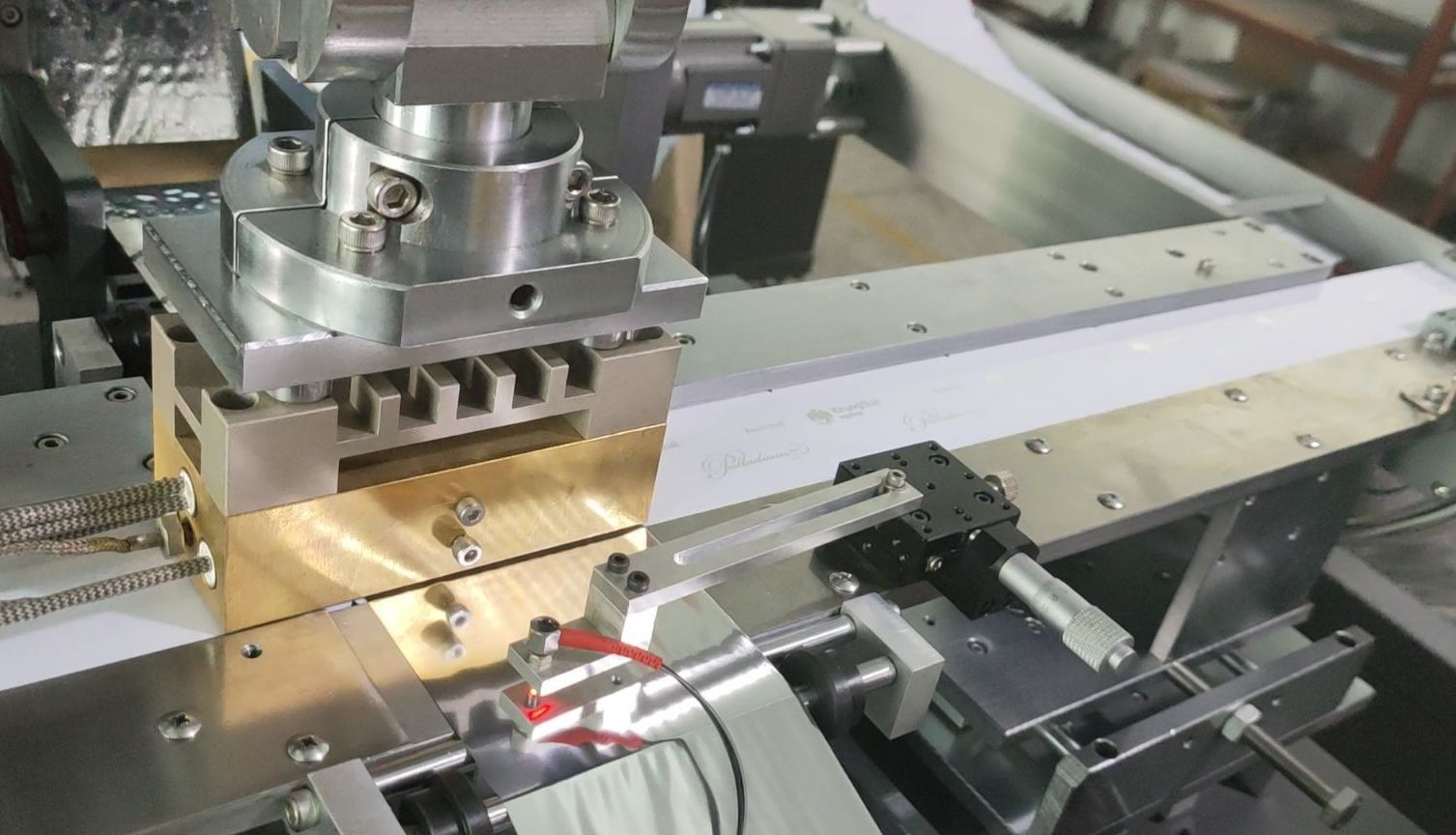

Automatic Card Hot Stamping Machine YHS-1

Automatic Card Hot Stamping Machine/ Card Hologram Foil Stamping Machine/Card Signature Panel Stamping

Machine YHS-1

1. Introduction of Automatic Card Hot Stamping Machine YHS-1

This machine is specially designed for hot stamping the anti-fake

hologram or signature panel for plastic cards, and it can also

stamp the words and patterns with gold or silver foil as well as

scratch-off foil stamping on cards surface. It is controlled by PLC

with friendly man-machine interface. It features high speed, good

stamping quality and precise location.

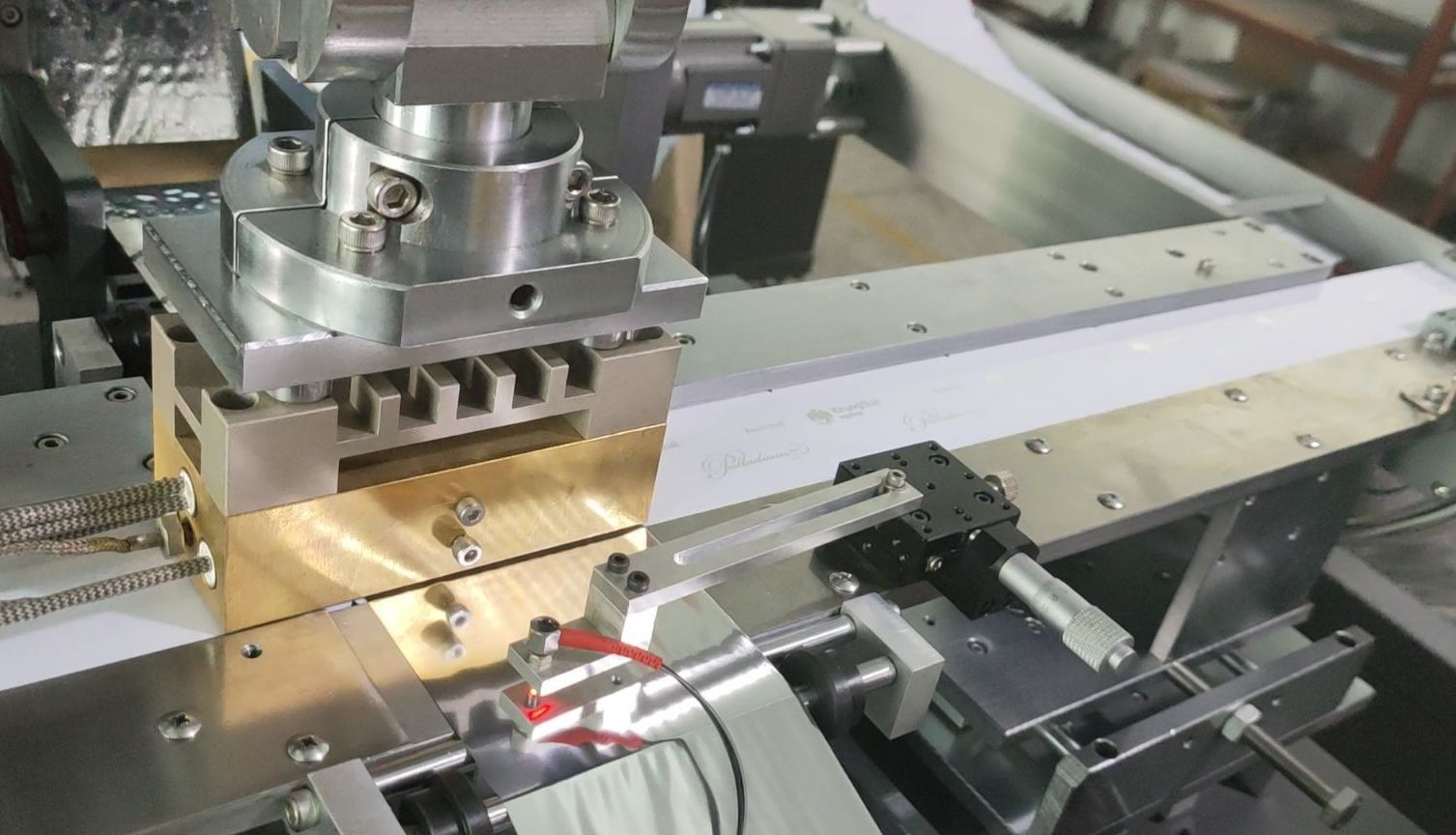

2. Feature Description of Automatic Card Hot Stamping Machine YHS-1

1. It applies high-quality servo motor as operation power to ensure

good stability and quality stamping. Running speed and pressing

stroke are adjustable.

2. Stepping distance for gilding film can be adjusted.

3. PLC control is adopted for reliable automatic running, and the

machine will halt and alarm automatically in case of no card or

failure occurring.

4. High-quality imported temperature controller is used to control

the hot stamping temperature for better stamping quality.

3. Technical Parameter of Automatic Card Hot Stamping Machine YHS-1

Power supply | AC 220V, 50/60 Hz |

Dimension | L1200mm×W820mm×H1580mm |

Weight | around 390 kg |

Control mode | PLC+ stepping system |

Compressed air | 6 KG/cm2 30L/min |

Speed | 3000 cards per hour |

Material | CR80 cards 0.50-0.85 mm thick |

Power | 2.5KW |

Position accuracy | ±0.2mm |

| Water cooling system | Provide temperature data output interface for cold water system. |

Stamping temperature range | 120-180 centigrade degrees (normally 140-150) |

Stamping area on card surface | no more than 48mm in card width direction and no more than 80mm in

card length direction |

4. More details of ACF Process Dual-interface Bank Card Milling and

Embedding Machine Pre-personalized YIME-ACF-1

Product First Pass Rate

| ≥99.8% |

Equipment utilization rate

| ≥98% |

Mean Time Between Major Failures (MTBF)

| ≥168h |

| X Y. Z-axis accuracy of chip slot milling equipment | ±0.015mm;Cpk>1.33 |

| Embedding accuracy of chip embedding machine | ±0.02mm;Cpk>1.33 |

| Speed-UPH | 4000 cards per hour for 1-chip card production |

Our service :

Pre-sale

(1) Professional suggestions (raw material matching, machine

selection, the condition of building factory, feasibility analysis

for brick machine production line)

(2) Device model choice (recommend the best machine according to

the raw material, capacity and the size of brick)

(3) Efficient on-line service

(4) Welcome to visit our factory and production line any time, if

you need, we can make invitation letter for you.

(5) Introduce the company file, product categories and production

process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients

side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at

clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well

communication with each other

Guarantee

(1)We can supply one year guarantee period for our card machines,

if the client have any question ,they could contact our service

department any time ,we will supply efficient service .

(2)Within one year ,if the client meet the unsolvable questions ,we

can make site supporting.